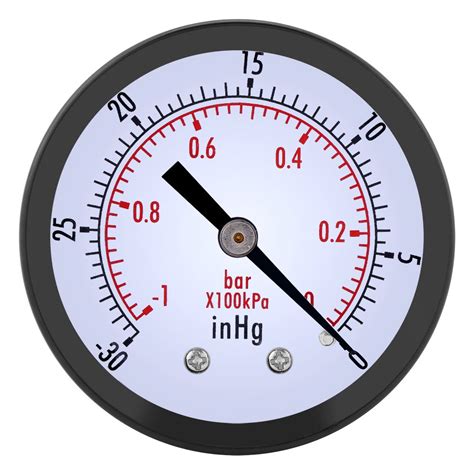

The concept of vacuum pressure meters is a crucial aspect of various industrial and scientific applications, where accurate measurement of pressure in a vacuum environment is essential. A vacuum pressure meter, also known as a vacuum gauge, is a device used to measure the pressure in a vacuum system. The pressure in a vacuum is typically measured in units of pressure, such as pascals (Pa), millibars (mbar), or inches of mercury (inHg). The choice of unit depends on the specific application and the level of precision required.

In a vacuum system, the pressure is typically much lower than atmospheric pressure, which is approximately 1013 mbar. The pressure in a vacuum can range from a few millibars to extremely low pressures, such as those found in ultra-high vacuum (UHV) systems, which can have pressures as low as 10^-10 mbar. The measurement of pressure in a vacuum is critical in various applications, including semiconductor manufacturing, thin-film deposition, and scientific research.

Key Points

- Vacuum pressure meters are used to measure the pressure in a vacuum system, which is essential in various industrial and scientific applications.

- The pressure in a vacuum is typically measured in units of pressure, such as pascals (Pa), millibars (mbar), or inches of mercury (inHg).

- The choice of unit depends on the specific application and the level of precision required.

- Vacuum pressure meters can be classified into different types, including mechanical, thermal, and ionization gauges.

- The selection of a vacuum pressure meter depends on the specific application, the level of precision required, and the operating conditions.

Vacuum Pressure Meter Types

There are several types of vacuum pressure meters, each with its own unique characteristics and applications. The most common types of vacuum pressure meters include mechanical, thermal, and ionization gauges. Mechanical gauges, such as Bourdon gauges, measure the pressure by detecting the deformation of a mechanical element, such as a diaphragm or a bellows. Thermal gauges, such as thermocouple gauges, measure the pressure by detecting the change in temperature of a gas or a liquid.

Ionization gauges, such as hot cathode ionization gauges, measure the pressure by detecting the ionization of gas molecules. These gauges are highly sensitive and can measure pressures as low as 10^-10 mbar. The selection of a vacuum pressure meter depends on the specific application, the level of precision required, and the operating conditions. For example, mechanical gauges are often used in applications where high precision is not required, while ionization gauges are used in applications where extremely low pressures need to be measured.

Operating Principles

The operating principle of a vacuum pressure meter depends on the type of gauge used. Mechanical gauges operate by detecting the deformation of a mechanical element, such as a diaphragm or a bellows, which is caused by the pressure difference between the inside and outside of the gauge. Thermal gauges operate by detecting the change in temperature of a gas or a liquid, which is caused by the pressure difference between the inside and outside of the gauge.

Ionization gauges operate by detecting the ionization of gas molecules, which is caused by the pressure difference between the inside and outside of the gauge. The ionization of gas molecules creates a current that is proportional to the pressure. The current is then measured and displayed on a meter or a digital display. The accuracy and precision of a vacuum pressure meter depend on the type of gauge used, the operating conditions, and the calibration of the gauge.

| Type of Gauge | Operating Principle | Pressure Range |

|---|---|---|

| Mechanical Gauge | Deformation of a mechanical element | 10^-3 mbar to 10^3 mbar |

| Thermal Gauge | Change in temperature of a gas or a liquid | 10^-3 mbar to 10^2 mbar |

| Ionization Gauge | Ionization of gas molecules | 10^-10 mbar to 10^-3 mbar |

Applications

Vacuum pressure meters have a wide range of applications in various industries, including semiconductor manufacturing, thin-film deposition, and scientific research. In semiconductor manufacturing, vacuum pressure meters are used to measure the pressure in the processing chambers, where the pressure needs to be controlled to ensure the quality of the semiconductors.

In thin-film deposition, vacuum pressure meters are used to measure the pressure in the deposition chamber, where the pressure needs to be controlled to ensure the quality of the thin films. In scientific research, vacuum pressure meters are used to measure the pressure in various experiments, such as those involving high-energy particles or extreme temperatures.

Advantages and Limitations

Vacuum pressure meters have several advantages, including high accuracy and precision, wide pressure range, and compact design. However, they also have some limitations, including high cost, complex calibration, and sensitivity to operating conditions. The cost of a vacuum pressure meter can be high, especially for high-precision gauges.

The calibration of a vacuum pressure meter can be complex and requires specialized equipment and expertise. The operating conditions, such as temperature and humidity, can affect the accuracy and precision of a vacuum pressure meter. It is essential to consider these limitations when selecting and using a vacuum pressure meter.

What is the difference between a mechanical and thermal vacuum pressure meter?

+A mechanical vacuum pressure meter measures the pressure by detecting the deformation of a mechanical element, while a thermal vacuum pressure meter measures the pressure by detecting the change in temperature of a gas or a liquid.

What is the pressure range of an ionization vacuum pressure meter?

+The pressure range of an ionization vacuum pressure meter is typically from 10^-10 mbar to 10^-3 mbar.

What are the advantages of using a vacuum pressure meter?

+The advantages of using a vacuum pressure meter include high accuracy and precision, wide pressure range, and compact design.

In conclusion, vacuum pressure meters are essential devices in various industrial and scientific applications, where accurate measurement of pressure in a vacuum environment is critical. The selection of a vacuum pressure meter depends on the specific application, the level of precision required, and the operating conditions. By understanding the operating principles, advantages, and limitations of vacuum pressure meters, users can select and use the most suitable gauge for their application.