The twist lock, a fundamental component in various mechanical systems, has been a cornerstone of secure and efficient connections for decades. Its simplicity, reliability, and effectiveness have made it an indispensable element in numerous applications, from industrial machinery to everyday devices. In this article, we will delve into the world of twist locks, exploring their history, design principles, applications, and the nuances that make them such a vital part of modern engineering.

Introduction to Twist Locks

A twist lock, by its most basic definition, is a type of fastener that requires a rotational motion to secure or release it. This simple yet ingenious mechanism has evolved over the years, with various designs and materials being introduced to cater to different needs and environments. From the humble beginnings in basic machinery to the sophisticated applications in aerospace and automotive industries, the twist lock has proven its versatility and value.

Historical Development

The concept of twist locks dates back to the early days of mechanical engineering, where the need for secure, quick, and reliable connections was first recognized. Over time, as industries evolved and new materials became available, the design and functionality of twist locks have undergone significant transformations. The introduction of new materials, such as stainless steel and advanced polymers, has further expanded the potential applications of twist locks, making them suitable for use in harsh environments and critical systems.

| Material | Properties | Applications |

|---|---|---|

| Stainless Steel | High strength, corrosion resistance | Marine, Food Processing |

| Advanced Polymers | Lightweight, chemical resistance | Aerospace, Automotive |

Design and Operation

The design of a twist lock typically involves a receptacle and a plug or a similar mating pair, where one part is designed to rotate relative to the other to effect the locking or unlocking action. The simplicity of this mechanism belies the complexity of the engineering that goes into its design, particularly in terms of ensuring secure connections, ease of use, and durability. The operation of a twist lock involves a straightforward process: the user applies a rotational force to the plug or the handle, which then engages or disengages the locking mechanism, securing or releasing the connection as needed.

Technical Specifications

Technical specifications for twist locks can vary widely depending on the application, including dimensions, material, torque requirements, and environmental resistance. For instance, a twist lock intended for underwater use would require specifications that ensure resistance to corrosion and the ability to function under water pressure. Similarly, a twist lock for aerospace applications would need to meet stringent standards for reliability, weight, and resistance to extreme temperatures.

Key Points

- Twist locks offer a secure and efficient means of connection, suitable for a wide range of applications.

- The choice of material is critical, influencing the lock's performance, durability, and application suitability.

- Design considerations must balance security, ease of use, and durability, with specifications tailored to the intended application.

- Twist locks have evolved to incorporate advanced materials and designs, expanding their potential applications.

- Understanding the technical specifications and operational requirements of twist locks is essential for their effective use and maintenance.

Applications and Industries

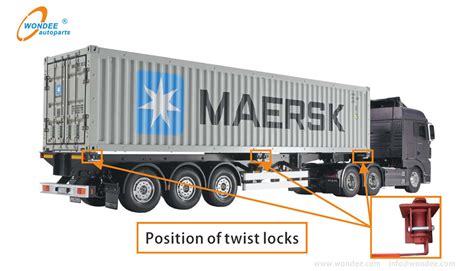

Twist locks find applications in numerous industries, including industrial machinery, aerospace, automotive, marine, and consumer products. Their versatility stems from their ability to provide a secure connection that is both easy to engage and disengage, making them ideal for applications where frequent connections and disconnections are necessary. In industrial settings, twist locks are used for securing machinery parts, while in the aerospace industry, they are critical for ensuring the integrity of aircraft systems.

Future Developments

As technology continues to advance, the future of twist locks holds promise for even more sophisticated designs and applications. The integration of smart materials and technologies, such as sensors and actuators, could lead to twist locks that not only provide secure connections but also offer real-time monitoring and automation capabilities. Furthermore, the development of new materials with enhanced properties, such as higher strength-to-weight ratios or improved corrosion resistance, will continue to expand the potential applications of twist locks.

What are the primary advantages of using twist locks?

+The primary advantages of twist locks include their ease of use, security, and the ability to provide a reliable connection that can be easily engaged and disengaged. They are also versatile and can be made from a variety of materials, making them suitable for different applications and environments.

How do I choose the right material for a twist lock?

+Choosing the right material for a twist lock involves considering the application, environment, and required properties such as strength, corrosion resistance, and weight. For instance, stainless steel might be chosen for marine applications due to its corrosion resistance, while advanced polymers might be preferred for aerospace applications due to their lightweight and chemical resistance properties.

Can twist locks be customized for specific applications?

+Yes, twist locks can be customized to meet the specific needs of different applications. This can involve modifying the design, choosing appropriate materials, and adjusting the technical specifications such as dimensions and torque requirements to ensure that the twist lock performs optimally in its intended use.

In conclusion, the twist lock represents a pinnacle of engineering simplicity and effectiveness, offering a reliable and efficient means of connection that has found its way into countless applications across various industries. As technology continues to evolve, it will be exciting to see how the design and application of twist locks adapt to meet new challenges and opportunities, further solidifying their place as a fundamental component in modern mechanical systems.