SMC fittings are a type of pneumatic fitting used in a wide range of applications, including industrial automation, medical devices, and food processing equipment. These fittings are designed to connect and control the flow of compressed air or other gases in pneumatic systems. SMC fittings are known for their high quality, reliability, and durability, making them a popular choice among manufacturers and engineers. In this article, we will explore the world of SMC fittings, including their types, applications, and benefits.

Key Points

- SMC fittings are used in various industries, including industrial automation, medical devices, and food processing equipment

- They are designed to connect and control the flow of compressed air or other gases in pneumatic systems

- SMC fittings are known for their high quality, reliability, and durability

- They offer a wide range of benefits, including ease of installation, compact design, and resistance to corrosion

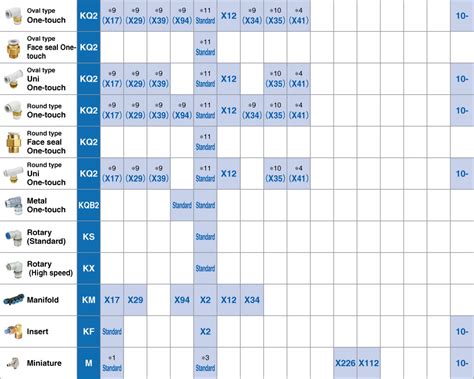

- SMC fittings are available in various types, including push-to-connect fittings, tube fittings, and hose fittings

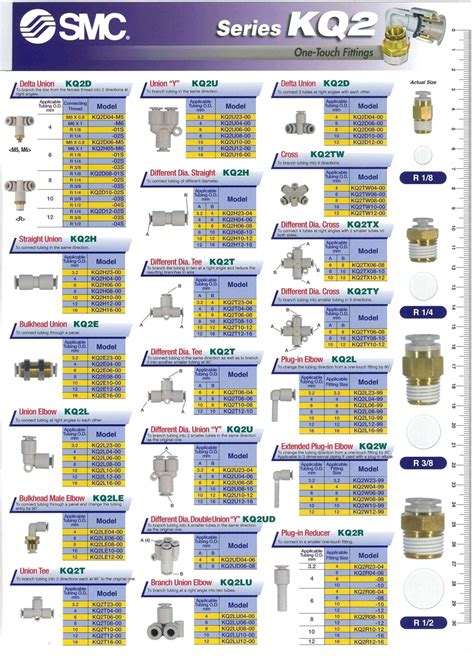

Types of SMC Fittings

SMC fittings come in a variety of types, each designed to meet specific application requirements. Some of the most common types of SMC fittings include push-to-connect fittings, tube fittings, and hose fittings. Push-to-connect fittings are designed for easy installation and offer a secure connection without the need for tools. Tube fittings, on the other hand, are designed for use with tubing and offer a reliable connection in applications where flexibility is required. Hose fittings are used to connect hoses to pneumatic systems and offer a durable and resistant connection.

Push-to-Connect Fittings

Push-to-connect fittings are a popular type of SMC fitting due to their ease of installation and secure connection. These fittings use a collet or sleeve to grip the tubing, providing a reliable connection without the need for tools. Push-to-connect fittings are available in a range of sizes and materials, including stainless steel, brass, and plastic. They are commonly used in applications where space is limited and a compact design is required.

| Fitting Type | Material | Size Range |

|---|---|---|

| Push-to-Connect | Stainless Steel, Brass, Plastic | 1/8" to 1" |

| Tube Fitting | Stainless Steel, Brass | 1/4" to 2" |

| Hose Fitting | Stainless Steel, Brass | 1/4" to 1" |

Applications of SMC Fittings

SMC fittings are used in a wide range of applications, including industrial automation, medical devices, and food processing equipment. In industrial automation, SMC fittings are used to control the flow of compressed air and other gases in pneumatic systems. In medical devices, SMC fittings are used in applications such as respiratory therapy, anesthesia, and surgical equipment. In food processing equipment, SMC fittings are used to control the flow of air and other gases in applications such as packaging, conveying, and cleaning.

Industrial Automation

In industrial automation, SMC fittings are used to control the flow of compressed air and other gases in pneumatic systems. They are commonly used in applications such as robotics, machine tools, and material handling equipment. SMC fittings offer a reliable and durable connection, making them an ideal choice for industrial automation applications.

SMC fittings also offer a range of benefits, including ease of installation, compact design, and resistance to corrosion. They are available in a range of materials, including stainless steel, brass, and plastic, making them suitable for use in a variety of applications. Additionally, SMC fittings are designed to meet the highest standards of quality and reliability, making them a popular choice among manufacturers and engineers.

What are the benefits of using SMC fittings?

+SMC fittings offer a range of benefits, including ease of installation, compact design, and resistance to corrosion. They are also designed to meet the highest standards of quality and reliability, making them a popular choice among manufacturers and engineers.

What types of SMC fittings are available?

+SMC fittings are available in a range of types, including push-to-connect fittings, tube fittings, and hose fittings. Each type is designed to meet specific application requirements and offers a reliable and durable connection.

What are the common applications of SMC fittings?

+SMC fittings are used in a wide range of applications, including industrial automation, medical devices, and food processing equipment. They are commonly used to control the flow of compressed air and other gases in pneumatic systems.

In conclusion, SMC fittings are a versatile and reliable component used in a wide range of applications. Their ease of installation, compact design, and resistance to corrosion make them an ideal choice for manufacturers and engineers. With their high quality, reliability, and durability, SMC fittings have become a popular choice in industries such as industrial automation, medical devices, and food processing equipment. Whether you’re designing a new system or maintaining an existing one, SMC fittings are an excellent option to consider.