The melting temperature of plastic materials is a critical parameter in various industrial applications, including manufacturing, packaging, and recycling. Understanding the melting points of different plastics is essential for designing and optimizing processes, ensuring product quality, and minimizing environmental impacts. In this article, we will delve into the world of plastic material melting temperatures, exploring the key factors that influence these temperatures, the various types of plastics and their corresponding melting points, and the significance of this knowledge in real-world applications.

Key Points

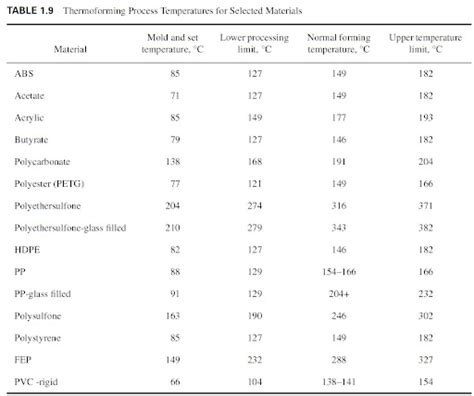

- The melting temperature of plastic materials ranges from approximately 100°C to 300°C, depending on the type of plastic.

- Polyethylene (PE) and polypropylene (PP) are two of the most commonly used plastics, with melting temperatures around 120°C and 160°C, respectively.

- Polyvinyl chloride (PVC) has a relatively low melting temperature of around 100°C, while polyethylene terephthalate (PET) has a higher melting temperature of around 260°C.

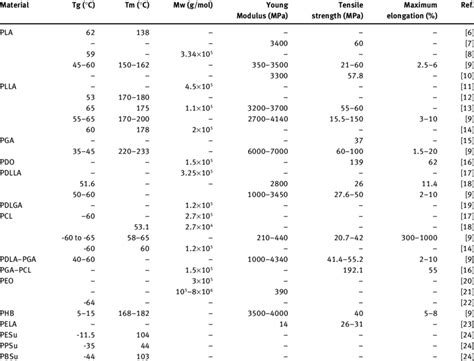

- The melting temperature of plastics can be influenced by factors such as molecular weight, crystallinity, and additives.

- Understanding the melting temperatures of plastics is crucial for designing and optimizing manufacturing processes, ensuring product quality, and minimizing environmental impacts.

Introduction to Plastic Material Melting Temperatures

Plastic materials are composed of long chains of molecules, known as polymers, which are held together by weak intermolecular forces. When heated, these molecules gain energy and begin to vibrate, eventually breaking free from their crystalline structure and transitioning into a molten state. The temperature at which this transition occurs is known as the melting point or melting temperature. The melting temperature of plastic materials is influenced by various factors, including the type of polymer, molecular weight, crystallinity, and additives.

Factors Influencing Melting Temperature

The melting temperature of plastics is affected by several key factors, including molecular weight, crystallinity, and additives. Molecular weight refers to the length of the polymer chains, with higher molecular weights generally resulting in higher melting temperatures. Crystallinity, on the other hand, refers to the degree of order in the polymer structure, with higher crystallinity leading to higher melting temperatures. Additives, such as plasticizers or fillers, can also impact the melting temperature of plastics by altering the intermolecular forces between the polymer chains.

| Plastic Material | Melting Temperature (°C) |

|---|---|

| Polyethylene (PE) | 120-140 |

| Polypropylene (PP) | 160-180 |

| Polyvinyl chloride (PVC) | 100-120 |

| Polyethylene terephthalate (PET) | 260-280 |

| Polycarbonate (PC) | 220-240 |

Types of Plastics and Their Melting Temperatures

There are numerous types of plastics, each with its unique melting temperature. Some of the most commonly used plastics include polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyethylene terephthalate (PET), and polycarbonate (PC). PE and PP are two of the most widely used plastics, with melting temperatures around 120°C and 160°C, respectively. PVC, on the other hand, has a relatively low melting temperature of around 100°C, while PET has a higher melting temperature of around 260°C.

Applications of Plastic Material Melting Temperatures

Understanding the melting temperatures of plastics is crucial in various industrial applications, including manufacturing, packaging, and recycling. In manufacturing, knowing the melting temperature of a plastic material is essential for designing and optimizing processes, such as injection molding and extrusion. In packaging, the melting temperature of plastics is critical for ensuring the integrity of packaged products, particularly in applications where temperature fluctuations are expected. In recycling, understanding the melting temperatures of plastics is vital for developing effective recycling processes and minimizing contamination.

What is the melting temperature of polyethylene?

+The melting temperature of polyethylene (PE) ranges from approximately 120°C to 140°C, depending on the specific type and grade of PE.

How does molecular weight affect the melting temperature of plastics?

+Molecular weight has a significant impact on the melting temperature of plastics, with higher molecular weights generally resulting in higher melting temperatures. This is because longer polymer chains have a greater number of intermolecular forces, requiring more energy to break and transition into a molten state.

What are the implications of melting temperature on plastic recycling?

+Understanding the melting temperatures of plastics is vital for developing effective recycling processes and minimizing contamination. By knowing the melting temperature of a plastic material, recyclers can design and optimize processes to ensure the production of high-quality recycled materials.

In conclusion, the melting temperature of plastic materials is a critical parameter in various industrial applications, including manufacturing, packaging, and recycling. By understanding the factors that influence melting temperature, such as molecular weight and crystallinity, and knowing the melting temperatures of various plastics, manufacturers and recyclers can design and optimize processes, ensuring product quality and minimizing environmental impacts. As research and development continue to advance, the importance of plastic material melting temperatures will only continue to grow, driving innovation and sustainability in the plastics industry.