The melting temperature of plastic is a critical parameter in understanding the physical and chemical properties of various plastic materials. Plastics, also known as polymers, are synthetic or semi-synthetic organic solids that can be molded or shaped. The melting point, or more accurately, the melting temperature range, of plastics varies widely depending on the type of polymer, its molecular structure, and the presence of additives or fillers. For instance, the melting temperature of polyethylene, one of the most common plastics, ranges from 105°C to 115°C, while that of polypropylene, another widely used plastic, ranges from 160°C to 180°C.

Understanding the melting temperature of plastics is crucial for various applications, including manufacturing, recycling, and safety assessments. In manufacturing, knowing the melting temperature helps in designing processes such as extrusion, injection molding, and blow molding. For recycling purposes, identifying the melting temperature is essential for sorting and processing different types of plastics, as it affects the recyclability and reusability of the material. Moreover, the melting temperature is a critical factor in safety evaluations, as it can influence the material's behavior under different environmental conditions, such as heat exposure.

Key Points

- The melting temperature of plastics varies depending on the type of polymer and its molecular structure.

- Understanding the melting temperature is crucial for manufacturing, recycling, and safety assessments of plastic materials.

- Different types of plastics have distinct melting temperature ranges, such as polyethylene (105°C to 115°C) and polypropylene (160°C to 180°C).

- The melting temperature affects the physical and chemical properties of plastics, influencing their applications and usability.

- Accurate identification of the melting temperature is essential for the efficient recycling and reprocessing of plastic materials.

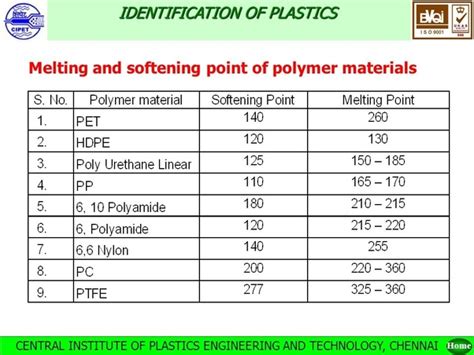

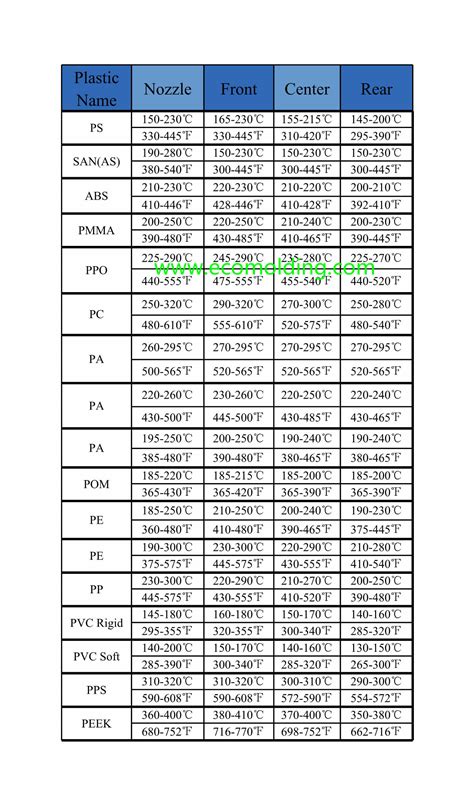

Types of Plastics and Their Melting Temperatures

Plastics can be broadly classified into several categories based on their properties and uses. Each type of plastic has a unique melting temperature range, which is determined by its chemical composition and molecular structure. For example, thermoplastics, such as polyethylene, polypropylene, and polyvinyl chloride (PVC), can be melted and reformed multiple times without undergoing significant chemical change. The melting temperatures of thermoplastics range from relatively low temperatures, such as 60°C for polyethylene terephthalate (PET), to higher temperatures, such as 260°C for polyetheretherketone (PEEK).

Thermoplastic Melting Temperatures

The melting temperatures of common thermoplastics are as follows: - Polyethylene (PE): 105°C to 115°C - Polypropylene (PP): 160°C to 180°C - Polyvinyl chloride (PVC): 100°C to 260°C - Polyethylene terephthalate (PET): 60°C to 80°C - Polyetheretherketone (PEEK): 260°C to 310°C These temperatures are not fixed values but rather ranges that can vary depending on the specific grade of the material, the presence of additives, and the conditions under which the material is processed.

| Type of Plastic | Melting Temperature Range |

|---|---|

| Polyethylene (PE) | 105°C to 115°C |

| Polypropylene (PP) | 160°C to 180°C |

| Polyvinyl chloride (PVC) | 100°C to 260°C |

| Polyethylene terephthalate (PET) | 60°C to 80°C |

| Polyetheretherketone (PEEK) | 260°C to 310°C |

Factors Influencing Melting Temperature

The melting temperature of plastics is influenced by several factors, including the molecular weight of the polymer, the degree of crystallinity, and the presence of additives or fillers. Higher molecular weight polymers generally have higher melting temperatures due to the increased intermolecular forces between the longer polymer chains. The degree of crystallinity also affects the melting temperature, as crystalline regions within the polymer require more energy to melt than amorphous regions. Additionally, the inclusion of additives or fillers can alter the melting behavior of plastics by introducing new interfaces and interactions that can either increase or decrease the melting temperature.

Molecular Weight and Crystallinity

The molecular weight and degree of crystallinity are intrinsic properties of the polymer that significantly influence its melting temperature. Polymers with higher molecular weights tend to have higher melting temperatures due to the stronger intermolecular forces between the longer polymer chains. Similarly, polymers with higher degrees of crystallinity require more energy to melt, resulting in higher melting temperatures. For example, high-density polyethylene (HDPE) has a higher melting temperature than low-density polyethylene (LDPE) due to its higher degree of crystallinity.

The understanding of the melting temperature of plastics and the factors that influence it is essential for the development of new plastic materials and the optimization of existing ones. By manipulating the molecular structure and composition of plastics, manufacturers can create materials with tailored properties for specific applications, contributing to advancements in fields such as packaging, automotive, aerospace, and biomedical devices.

What is the melting temperature of common plastics like polyethylene and polypropylene?

+The melting temperature of polyethylene ranges from 105°C to 115°C, while that of polypropylene ranges from 160°C to 180°C. These temperatures can vary based on the specific type and grade of the plastic.

How does the molecular weight of a polymer affect its melting temperature?

+Polymers with higher molecular weights generally have higher melting temperatures due to the increased intermolecular forces between the longer polymer chains.

What role does crystallinity play in the melting temperature of plastics?

+The degree of crystallinity affects the melting temperature, as crystalline regions within the polymer require more energy to melt than amorphous regions, resulting in higher melting temperatures for more crystalline polymers.

In conclusion, the melting temperature of plastics is a complex property influenced by the molecular structure, composition, and processing conditions of the material. Understanding these factors and how they interact is crucial for the development of new plastic materials, the optimization of manufacturing processes, and the efficient recycling of plastic waste. As the world continues to rely heavily on plastic materials, advancements in our understanding of their physical and chemical properties will play a vital role in addressing the challenges associated with plastic use and disposal.