The relationship between carbon content and the hardness of steel is a fundamental concept in metallurgy. Steel is an alloy of iron and carbon, and the amount of carbon present significantly affects its mechanical properties, including hardness. Generally, as the carbon content in steel increases, the hardness also increases, but only up to a certain point. This is because carbon is a key element that influences the microstructure of steel, with higher carbon contents typically leading to the formation of harder microconstituents.

Carbon Content and Steel Hardness

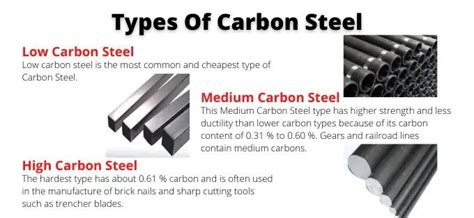

Low carbon steels, which contain up to 0.3% carbon, are softer and more ductile. They are often used in applications where formability and weldability are crucial, such as in the automotive and construction industries. Medium carbon steels, with carbon contents ranging from 0.3% to 0.6%, offer a balance between strength, hardness, and ductility. They are used in a wide range of applications, including machinery parts and axles. High carbon steels, containing more than 0.6% carbon, are harder and less ductile. They are commonly used for making tools, springs, and high-strength wires.

Effects of Higher Carbon Content

As the carbon content increases, the steel’s microstructure changes, leading to an increase in hardness. This is due to the formation of pearlite, a microconstituent that is harder than the ferrite found in low carbon steels. Additionally, higher carbon steels can be heat-treated to form even harder microstructures, such as martensite, through processes like quenching and tempering. However, very high carbon contents (above 1.5%) can lead to the formation of carbides, which, while very hard, can also make the steel more brittle and less tough.

| Carbon Content (%) | Steel Type | Hardness (HB) |

|---|---|---|

| 0.1-0.3 | Low Carbon Steel | 50-100 |

| 0.3-0.6 | Medium Carbon Steel | 100-200 |

| 0.6-1.0 | High Carbon Steel | 200-400 |

| 1.0-1.5 | Very High Carbon Steel | 400-600 |

Key Points

- Higher carbon content in steel typically increases its hardness up to a certain point.

- Low carbon steels (<0.3% C) are softer and more ductile, used in applications requiring formability and weldability.

- Medium carbon steels (0.3-0.6% C) balance strength, hardness, and ductility, suitable for machinery parts and axles.

- High carbon steels (>0.6% C) are harder and less ductile, used for tools, springs, and high-strength wires.

- The hardness of steel also depends on the heat treatment process, with higher carbon steels capable of forming very hard microstructures through quenching and tempering.

In conclusion, the hardness of steel is directly influenced by its carbon content, with higher carbon contents generally leading to harder steels. However, the relationship is not entirely linear, as very high carbon contents can introduce brittleness. Understanding this relationship is essential for selecting the appropriate steel type for specific applications, ensuring the optimal balance of mechanical properties.

How does the carbon content affect the weldability of steel?

+Higher carbon content in steel can make it more difficult to weld because it can lead to the formation of hard, brittle microstructures in the heat-affected zone. Low carbon steels are generally more weldable due to their lower hardness and higher ductility.

What is the purpose of heat treatment in high carbon steels?

+Heat treatment, such as quenching and tempering, is used to alter the microstructure of high carbon steels, allowing for the achievement of specific mechanical properties. This process can significantly increase the hardness and strength of the steel, making it suitable for applications requiring high performance.

Can very high carbon steels be used for structural applications?

+While very high carbon steels offer exceptional hardness, their use in structural applications is limited due to their potential brittleness. For most structural uses, a balance between strength, toughness, and ductility is required, making medium or low carbon steels more appropriate.