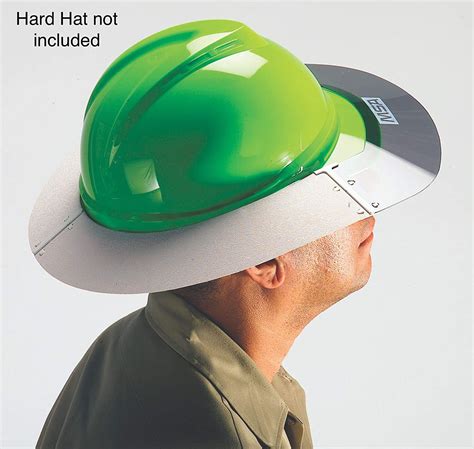

The hard hat visor is a crucial component of personal protective equipment (PPE) in various industries, including construction, manufacturing, and mining. Its primary function is to protect the face and eyes from hazards such as falling objects, flying particles, and chemical splashes. In this article, we will delve into the world of hard hat visors, exploring their types, features, and benefits, as well as the importance of proper selection and maintenance.

Key Points

- Hard hat visors provide essential protection for the face and eyes in hazardous work environments.

- There are several types of hard hat visors, including fixed, flip-up, and retractable models.

- Visor materials and coatings can enhance visibility, reduce glare, and improve scratch resistance.

- Proper selection and maintenance of hard hat visors are critical to ensuring optimal protection and compliance with safety regulations.

- Regular inspection and replacement of visors can help prevent accidents and reduce the risk of eye injuries.

Types of Hard Hat Visors

Hard hat visors come in various designs to cater to different needs and preferences. The most common types include:

- Fixed visors: These are permanently attached to the hard hat and provide continuous protection.

- Flip-up visors: These can be flipped up or down, allowing for easy access and visibility when not in use.

- Retractable visors: These can be retracted into the hard hat when not in use, providing a more compact design.

Each type has its advantages and disadvantages, and the choice of visor ultimately depends on the specific work environment, personal preference, and regulatory requirements.

Visor Materials and Coatings

Hard hat visors are typically made from polycarbonate or acetate materials, which offer excellent impact resistance and optical clarity. Some visors may also feature specialized coatings, such as:

- Anti-fog coatings: These help to prevent fogging and misting, ensuring clear visibility in humid or cold environments.

- Anti-scratch coatings: These provide an additional layer of protection against scratches and abrasions, extending the lifespan of the visor.

- UV-resistant coatings: These help to block out harmful ultraviolet (UV) radiation, reducing eye strain and discomfort.

These coatings can significantly enhance the performance and durability of the visor, making them an essential consideration when selecting a hard hat visor.

| Visor Material | Optical Clarity | Impact Resistance |

|---|---|---|

| Polycarbonate | 90% | High |

| Acetate | 85% | Medium |

Importance of Proper Selection and Maintenance

Proper selection and maintenance of hard hat visors are critical to ensuring optimal protection and compliance with safety regulations. This includes:

- Regular inspection: Visors should be inspected regularly for signs of damage, scratches, or wear.

- Proper cleaning: Visors should be cleaned regularly to prevent the buildup of dirt, grime, or other substances that can impair visibility.

- Replacement: Visors should be replaced immediately if they are damaged or show signs of excessive wear.

Failure to properly select and maintain hard hat visors can result in reduced protection, increased risk of eye injuries, and non-compliance with safety regulations.

Regulatory Compliance

Hard hat visors must comply with various regulatory standards, including those set by the Occupational Safety and Health Administration (OSHA) and the American National Standards Institute (ANSI). These standards specify requirements for visor materials, design, and performance, ensuring that visors provide adequate protection for workers.

Employers and workers must ensure that their hard hat visors meet these regulatory requirements, and that they are properly selected, maintained, and used in accordance with the manufacturer’s instructions and industry best practices.

What is the purpose of a hard hat visor?

+The purpose of a hard hat visor is to protect the face and eyes from hazards such as falling objects, flying particles, and chemical splashes.

What types of hard hat visors are available?

+There are several types of hard hat visors, including fixed, flip-up, and retractable models.

How often should hard hat visors be inspected and replaced?

+Hard hat visors should be inspected regularly and replaced immediately if they are damaged or show signs of excessive wear.

Meta Description: Learn about the importance of hard hat visors in protecting workers from hazards and injuries. Discover the different types of visors, materials, and coatings, and understand the regulatory requirements and best practices for selection, maintenance, and use.