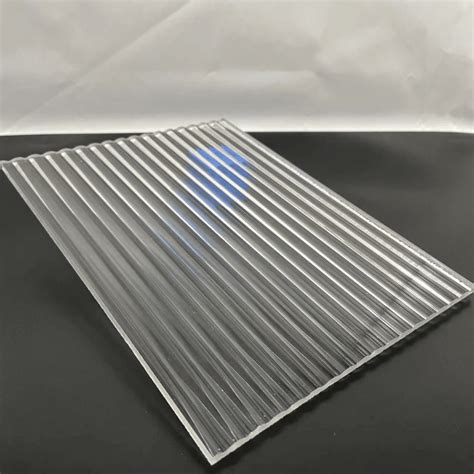

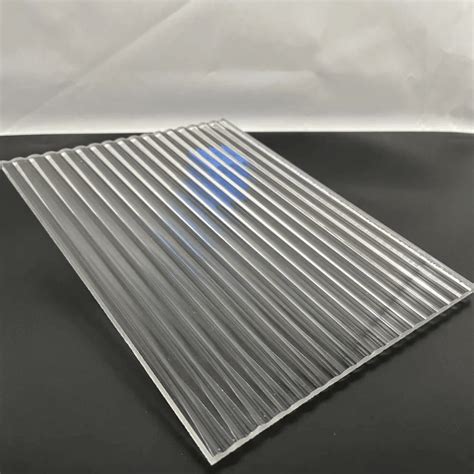

Fluted plastic sheets, also known as corrugated plastic sheets, are a type of plastic material that has gained popularity in various industries due to their unique characteristics and benefits. These sheets are made from a combination of polypropylene and polyethylene materials, which provide them with excellent durability, flexibility, and resistance to chemicals and UV light. The fluted design of these sheets, which features a series of parallel ridges and grooves, offers additional strength and stability, making them ideal for applications where rigidity and impact resistance are crucial.

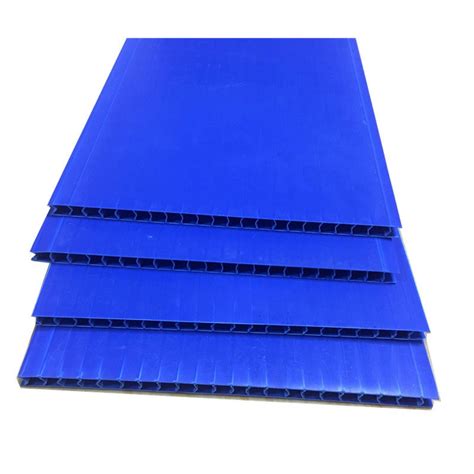

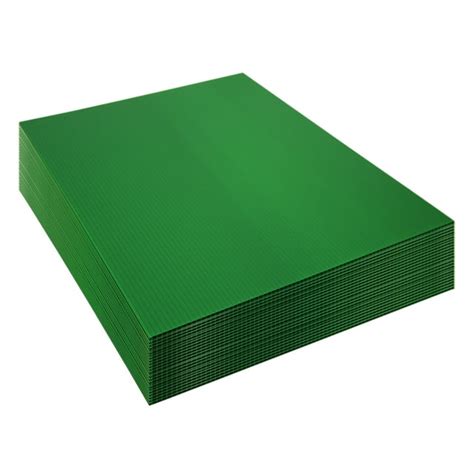

The production process of fluted plastic sheets involves the extrusion of plastic materials, followed by the formation of the corrugated pattern through a series of rollers. This process allows for the creation of sheets with varying thicknesses, widths, and lengths, making them suitable for a wide range of applications. The sheets can be customized with different colors, textures, and finishes, further expanding their potential uses. With their lightweight, waterproof, and easy-to-clean properties, fluted plastic sheets have become a preferred choice for many industries, including construction, packaging, and graphics.

Key Points

- Fluted plastic sheets are made from a combination of polypropylene and polyethylene materials, providing excellent durability and resistance to chemicals and UV light.

- The corrugated design of these sheets offers additional strength and stability, making them ideal for applications where rigidity and impact resistance are crucial.

- Fluted plastic sheets can be customized with different colors, textures, and finishes, expanding their potential uses.

- These sheets are lightweight, waterproof, and easy to clean, making them a preferred choice for many industries, including construction, packaging, and graphics.

- Fluted plastic sheets are an environmentally friendly alternative to traditional materials, as they are reusable and recyclable.

Properties and Benefits of Fluted Plastic Sheets

Fluted plastic sheets exhibit a range of properties that make them an attractive option for various applications. Their corrugated design provides excellent strength-to-weight ratio, allowing them to withstand heavy loads and impacts without compromising their structural integrity. Additionally, the sheets are resistant to chemicals, UV light, and moisture, making them suitable for use in harsh environments. The smooth surface of the sheets also makes them easy to clean and maintain, reducing the risk of contamination and damage.

The benefits of fluted plastic sheets are numerous, ranging from their cost-effectiveness to their environmental sustainability. Compared to traditional materials, such as wood or metal, fluted plastic sheets are more affordable and require less maintenance. They are also reusable and recyclable, reducing waste and minimizing their carbon footprint. Furthermore, the sheets are lightweight and easy to handle, making them ideal for applications where weight and portability are crucial.

Applications of Fluted Plastic Sheets

Fluted plastic sheets have a wide range of applications across various industries. In construction, they are used as a durable and waterproof material for roofing, siding, and insulation. In packaging, they are used to create custom boxes, crates, and containers that are resistant to impact and moisture. In graphics, they are used to create eye-catching displays, signs, and banners that are lightweight and easy to install. Other applications include agriculture, where they are used as a durable and UV-resistant material for greenhouses and irrigation systems, and logistics, where they are used as a lightweight and cost-effective material for pallets and cargo containers.

| Industry | Application | Benefits |

|---|---|---|

| Construction | Roofing, siding, insulation | Durability, waterproof, cost-effective |

| Packaging | Custom boxes, crates, containers | Impact resistance, moisture resistance, lightweight |

| Graphics | Displays, signs, banners | Eye-catching, lightweight, easy to install |

| Agriculture | Greenhouses, irrigation systems | Durability, UV resistance, cost-effective |

| Logistics | Pallets, cargo containers | Lightweight, cost-effective, reusable |

Technical Specifications and Manufacturing Process

The technical specifications of fluted plastic sheets vary depending on the manufacturer and the intended application. However, most sheets are made from a combination of polypropylene and polyethylene materials, with a corrugated design that provides additional strength and stability. The sheets can be customized with different thicknesses, widths, and lengths, as well as different colors, textures, and finishes.

The manufacturing process of fluted plastic sheets involves the extrusion of plastic materials, followed by the formation of the corrugated pattern through a series of rollers. The sheets are then cut to size and finished with a variety of treatments, such as printing, laminating, or coating. The manufacturing process can be tailored to meet specific requirements, such as UV resistance, chemical resistance, or flame retardancy.

Environmental Sustainability and Recycling

Fluted plastic sheets are an environmentally friendly alternative to traditional materials, as they are reusable and recyclable. The sheets can be recycled at the end of their life cycle, reducing waste and minimizing their carbon footprint. Additionally, the sheets are made from a combination of polypropylene and polyethylene materials, which are themselves recyclable and reusable.

The environmental benefits of fluted plastic sheets are numerous, ranging from their reduced waste and energy consumption to their lower greenhouse gas emissions. Compared to traditional materials, such as wood or metal, fluted plastic sheets require less energy to produce and transport, reducing their carbon footprint and environmental impact. Furthermore, the sheets are durable and long-lasting, reducing the need for frequent replacements and waste generation.

What are the benefits of using fluted plastic sheets?

+Fluted plastic sheets offer a range of benefits, including durability, flexibility, resistance to chemicals and UV light, and cost-effectiveness. They are also lightweight, waterproof, and easy to clean, making them ideal for applications where performance and sustainability are crucial.

What are the common applications of fluted plastic sheets?

+Fluted plastic sheets have a wide range of applications across various industries, including construction, packaging, graphics, agriculture, and logistics. They are used as a durable and waterproof material for roofing, siding, and insulation, as well as for custom boxes, crates, and containers.

How are fluted plastic sheets manufactured?

+The manufacturing process of fluted plastic sheets involves the extrusion of plastic materials, followed by the formation of the corrugated pattern through a series of rollers. The sheets are then cut to size and finished with a variety of treatments, such as printing, laminating, or coating.

Are fluted plastic sheets environmentally friendly?

+Yes, fluted plastic sheets are an environmentally friendly alternative to traditional materials, as they are reusable and recyclable. The sheets can be recycled at the end of their life cycle, reducing waste and minimizing their carbon footprint.

What are the technical specifications of fluted plastic sheets?

+The technical specifications of fluted plastic sheets vary depending on the manufacturer and the intended application. However, most sheets are made from a combination of polypropylene and polyethylene materials, with a corrugated design that provides additional strength and stability.