Dtm paint, also known as Dry-to-Match paint, has revolutionized the way automotive and industrial coatings are applied. This innovative technology allows for a unique painting process that eliminates the need for a separate clear coat, thereby reducing production time and increasing efficiency. The development of dtm paint has been a significant milestone in the coatings industry, with its impact felt across various sectors, from automotive manufacturing to aerospace and beyond.

Understanding Dtm Paint Technology

The core principle behind dtm paint lies in its ability to dry to a hard, glossy finish without the need for an additional clear coat. This is achieved through the use of specialized resins and additives that enhance the paint’s durability and appearance. By integrating the properties of both the base coat and clear coat into a single layer, dtm paint simplifies the painting process, reducing material costs and environmental impact. The technology has undergone significant advancements over the years, with modern dtm paints offering improved scratch resistance, UV stability, and color retention.

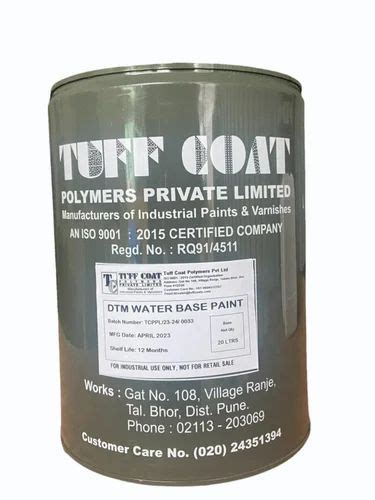

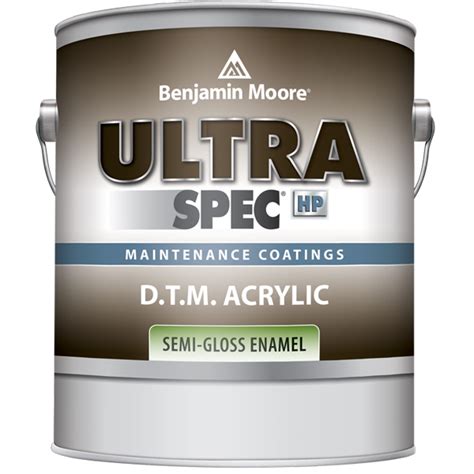

Applications of Dtm Paint

The versatility of dtm paint has led to its widespread adoption across various industries. In the automotive sector, dtm paint is used for coating vehicle bodies, wheels, and other components. Its use has been particularly notable in the production of high-performance vehicles, where the need for lightweight, durable coatings is paramount. Beyond automotive, dtm paint is applied in the aerospace industry for coating aircraft components, due to its resistance to extreme temperatures and corrosive environments. Additionally, dtm paint is used in industrial settings for coating machinery, equipment, and furniture, where its durability and ease of application are highly valued.

| Industry | Application | Benefits |

|---|---|---|

| Automotive | Vehicle bodies, wheels | Reduced production time, increased durability |

| Aerospace | Aircraft components | Resistance to extreme temperatures, lightweight |

| Industrial | Machinery, equipment, furniture | Durability, ease of application, cost savings |

Key Points

- Dtm paint eliminates the need for a separate clear coat, simplifying the painting process and reducing costs.

- Its applications span across the automotive, aerospace, and industrial sectors, due to its durability, ease of use, and lightweight properties.

- Ongoing research aims to further enhance dtm paint's performance, particularly in terms of sustainability and environmental impact.

- The technology has the potential to revolutionize manufacturing processes, offering significant advantages in production efficiency and product quality.

- Understanding the chemistry behind dtm paint is crucial for optimizing its application and realizing its full potential in various industries.

Technical Specifications and Performance

The technical specifications of dtm paint are as varied as its applications, with different formulations designed to meet the specific needs of each industry. In general, dtm paints are characterized by their high solids content, which contributes to their durability and resistance to environmental degradation. The performance of dtm paint is typically evaluated based on its adhesion, hardness, and color retention, among other factors. Advanced testing methods, including spectroscopy and accelerated weathering tests, are used to assess the long-term durability of dtm coatings.

Environmental and Safety Considerations

The development and application of dtm paint have also been influenced by environmental and safety concerns. Modern dtm paints are formulated to be more environmentally friendly, with lower VOC (Volatile Organic Compound) emissions and reduced waste generation. Furthermore, the simplified painting process facilitated by dtm technology can lead to energy savings and a decrease in the carbon footprint of manufacturing operations. Safety considerations are also paramount, with dtm paints designed to meet stringent standards for toxicity and flammability.

What are the primary advantages of using dtm paint?

+The primary advantages of dtm paint include its ability to simplify the painting process, reduce production time, and increase durability. It also offers environmental benefits by reducing VOC emissions and waste generation.

How does dtm paint compare to traditional painting methods in terms of cost?

+Dtm paint can offer significant cost savings compared to traditional methods, primarily due to the elimination of the clear coat and the reduction in labor and material costs associated with its application.

What industries benefit the most from the use of dtm paint?

+The automotive, aerospace, and industrial sectors are among the primary beneficiaries of dtm paint technology, due to its durability, lightweight properties, and ease of application.

In conclusion, dtm paint represents a significant advancement in coating technology, offering a unique combination of durability, ease of application, and environmental sustainability. As research and development continue to push the boundaries of what is possible with dtm paint, its potential to transform manufacturing processes and contribute to a more sustainable future becomes increasingly evident. Whether in the automotive, aerospace, or industrial sectors, the impact of dtm paint is undeniable, marking a new era in the application of coatings and the pursuit of innovation in materials science.