The use of divider plastics has become an essential component in various industries, including manufacturing, logistics, and retail. Divider plastics, also known as plastic dividers or partition sheets, are designed to separate and organize products, materials, or components within a container, palette, or storage facility. These plastics are typically made from durable, flexible materials such as polyethylene, polypropylene, or PVC, which can withstand the rigors of repeated use and handling.

Types of Divider Plastics

There are several types of divider plastics available, each with its unique characteristics, advantages, and applications. Some of the most common types include:

- Corrugated plastic dividers: These dividers feature a corrugated design, which provides added strength, rigidity, and protection against damage. They are often used in the packaging and shipping of fragile or sensitive items.

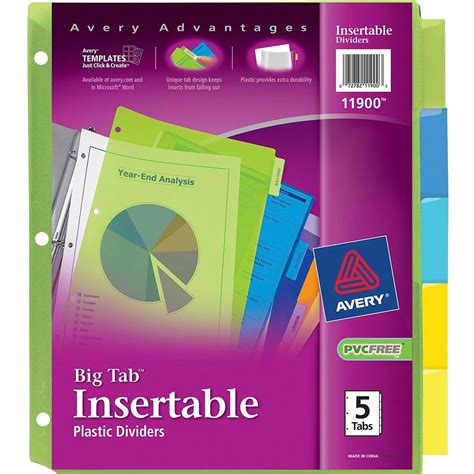

- Flat plastic dividers: These dividers are made from a flat, rigid plastic material and are commonly used in storage and organization applications, such as separating files, documents, or inventory items.

- Foldable plastic dividers: These dividers are designed to be folded and collapsed, making them easy to store and transport. They are often used in temporary or seasonal applications, such as separating products at trade shows or events.

Benefits of Divider Plastics

The use of divider plastics offers several benefits, including:

- Improved organization and efficiency: Divider plastics help to separate and categorize products, materials, or components, making it easier to locate and access what is needed.

- Enhanced protection and safety: Divider plastics can help to prevent damage, scratches, or other forms of damage to products or materials during storage or transportation.

- Increased storage capacity: By separating and organizing products or materials, divider plastics can help to maximize storage capacity and reduce waste.

| Divider Plastic Type | Thickness | Material |

|---|---|---|

| Corrugated Plastic Divider | 1/8 inch | Polypropylene |

| Flat Plastic Divider | 1/16 inch | Polyethylene |

| Foldable Plastic Divider | 1/32 inch | PVC |

Key Points

- Divider plastics are used to separate and organize products, materials, or components in various industries.

- Corrugated, flat, and foldable plastic dividers are common types, each with unique characteristics and applications.

- Benefits of divider plastics include improved organization, enhanced protection, and increased storage capacity.

- Material type and thickness are critical factors in selecting the right divider plastic for a specific application.

- Proper selection and use of divider plastics can help to maximize efficiency, reduce waste, and improve overall productivity.

Applications of Divider Plastics

Divider plastics have a wide range of applications across various industries, including:

- Manufacturing and production: Divider plastics are used to separate and organize components, parts, or materials during the manufacturing process.

- Logistics and shipping: Divider plastics help to protect and separate products during transportation, reducing damage and improving delivery times.

- Retail and point-of-sale: Divider plastics are used to organize and display products, making it easier for customers to find what they need.

Technical Specifications and Considerations

When selecting divider plastics, it’s essential to consider the technical specifications and requirements of the application, including:

- Material compatibility: Ensuring that the divider plastic is compatible with the products or materials being stored or transported.

- Temperature and humidity resistance: Selecting divider plastics that can withstand the temperature and humidity conditions of the application.

- Strength and durability: Choosing divider plastics that can withstand the rigors of repeated use and handling.

What are the most common types of divider plastics?

+The most common types of divider plastics include corrugated, flat, and foldable plastic dividers, each with its unique characteristics and applications.

What are the benefits of using divider plastics?

+The benefits of using divider plastics include improved organization and efficiency, enhanced protection and safety, and increased storage capacity.

How do I choose the right divider plastic for my application?

+When choosing a divider plastic, consider the specific application, material type, and thickness to ensure optimal performance and durability. It’s also essential to consider factors such as material compatibility, temperature and humidity resistance, and strength and durability.

Related Terms:

- Plastic divider inserts

- Hard Plastic dividers

- Large Plastic Dividers

- Plastic Divider Wall

- Hard Plastic file Dividers

- Plastic Divider Tray