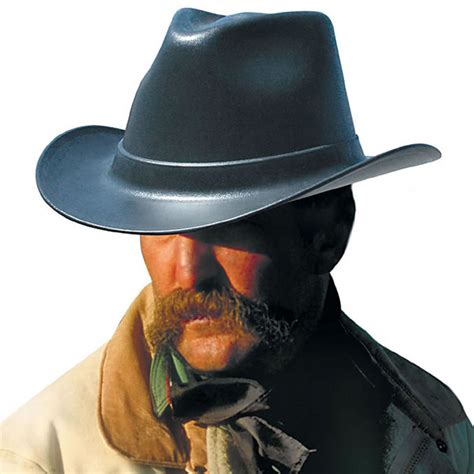

The cowboy hard hat, a staple of American workwear, has a rich history that spans over a century. Also known as a cowboy helmet or western hard hat, this type of headgear has been a mainstay of the construction, oil, and gas industries, particularly in the southern United States. The design of the cowboy hard hat is modeled after the traditional cowboy hat, with a wide brim and a high crown, but it is made from a hard plastic or fiberglass material to provide protection from falling objects and other hazards on the job site.

History of the Cowboy Hard Hat

The concept of the cowboy hard hat dates back to the early 20th century, when workers in the oil and gas industries began wearing traditional cowboy hats to protect themselves from the sun and other environmental elements. However, these hats were not designed to provide protection from falling objects or other hazards, and workers often suffered head injuries as a result. In response to this need, manufacturers began developing hard hats that were designed to resemble the traditional cowboy hat, but with a harder, more protective material. The first cowboy hard hats were made from steel and were quite heavy, but they provided excellent protection for workers. Over time, lighter materials such as plastic and fiberglass were developed, making the cowboy hard hat more comfortable and practical for workers to wear.

Design and Features

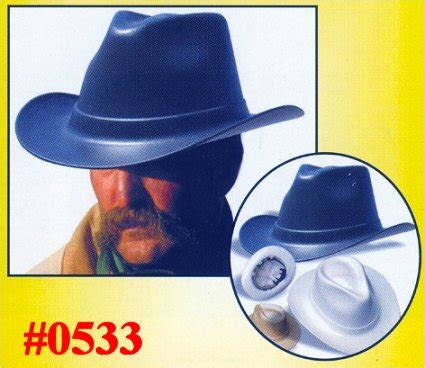

The design of the cowboy hard hat is characterized by its wide brim and high crown, which provides excellent protection from the sun and other environmental elements. The hat is typically made from a hard plastic or fiberglass material, which is molded to fit the shape of the head. The hat usually has a chin strap or other type of retention system to keep it securely in place, and may also have a suspension system to help absorb the impact of falling objects. Some cowboy hard hats also have additional features such as ventilation systems to help keep the head cool, and reflective strips to increase visibility in low-light conditions.

| Feature | Description |

|---|---|

| Material | Hard plastic or fiberglass |

| Design | Wide brim and high crown |

| Retention System | Chin strap or other type of retention system |

| Suspension System | Helps absorb the impact of falling objects |

| Ventilation System | Helps keep the head cool |

| Reflective Strips | Increases visibility in low-light conditions |

Key Points

- The cowboy hard hat has a rich history that spans over a century

- The design of the cowboy hard hat is modeled after the traditional cowboy hat, but made from a hard plastic or fiberglass material

- The hat provides excellent protection from falling objects and other hazards on the job site

- The cowboy hard hat is a popular choice among workers in the construction, oil, and gas industries

- The hat is available with a range of features, including ventilation systems and reflective strips

Standards and Certifications

The cowboy hard hat must meet certain standards and certifications in order to be considered safe for use on the job site. In the United States, the Occupational Safety and Health Administration (OSHA) sets the standards for hard hats, and the American National Standards Institute (ANSI) provides certification for hard hats that meet these standards. The ANSI standard for hard hats is Z89.1, which outlines the requirements for impact resistance, penetration resistance, and other factors. Hard hats that meet this standard are labeled with a specific classification, such as Type I or Type II, which indicates the level of protection provided.

Types of Cowboy Hard Hats

There are several types of cowboy hard hats available, each with its own unique features and benefits. Type I hard hats are designed to provide protection from objects falling from above, and are typically used in construction and other industries where workers are at risk of being struck by falling objects. Type II hard hats are designed to provide protection from objects falling from the side, and are typically used in industries such as oil and gas, where workers may be at risk of being struck by equipment or other objects. There are also hard hats available that are designed to provide protection from electrical hazards, and these are typically used in industries such as electrical contracting and telecommunications.

What is the history of the cowboy hard hat?

+The cowboy hard hat has a rich history that spans over a century, dating back to the early 20th century when workers in the oil and gas industries began wearing traditional cowboy hats to protect themselves from the sun and other environmental elements.

What are the features of a cowboy hard hat?

+The cowboy hard hat typically has a wide brim and high crown, and is made from a hard plastic or fiberglass material. It may also have additional features such as ventilation systems, reflective strips, and a suspension system to help absorb the impact of falling objects.

What are the standards and certifications for cowboy hard hats?

+The cowboy hard hat must meet certain standards and certifications in order to be considered safe for use on the job site. In the United States, the Occupational Safety and Health Administration (OSHA) sets the standards for hard hats, and the American National Standards Institute (ANSI) provides certification for hard hats that meet these standards.

In conclusion, the cowboy hard hat is an essential piece of safety equipment for workers in the construction, oil, and gas industries. Its rich history, unique design, and range of features make it an excellent option for those who need protection from falling objects and other hazards on the job site. By understanding the standards and certifications for cowboy hard hats, workers can ensure that they are wearing a safe and effective hard hat that meets their needs.