When it comes to choosing the right material for a specific application, two popular options often come to mind: carbon and stainless steel. Both materials have their unique properties, advantages, and disadvantages, making them suitable for different uses. In this article, we will delve into the world of carbon and stainless steel, exploring their differences, applications, and the factors that set them apart.

Key Points

- Carbon and stainless steel have distinct properties that make them suitable for different applications

- Carbon is a versatile material with high strength-to-weight ratio, corrosion resistance, and thermal conductivity

- Stainless steel is renowned for its corrosion resistance, durability, and aesthetic appeal

- The choice between carbon and stainless steel depends on factors such as cost, weight, and environmental conditions

- Both materials have their limitations, including carbon's susceptibility to fatigue and stainless steel's high cost

Properties of Carbon and Stainless Steel

Carbon, in its various forms, is a highly versatile material. It can be found in nature as graphite, diamond, or fullerenes, each with unique properties. When combined with other elements, carbon forms a wide range of compounds, including fibers, nanotubes, and polymers. Carbon’s high strength-to-weight ratio, corrosion resistance, and thermal conductivity make it an attractive material for various applications, from aerospace to sports equipment.

Stainless steel, on the other hand, is a type of alloy that consists of iron, chromium, and other elements. Its corrosion resistance, durability, and aesthetic appeal have made it a popular choice for construction, automotive, and consumer products. Stainless steel's ability to withstand harsh environments and maintain its appearance over time has earned it a reputation as a premium material.

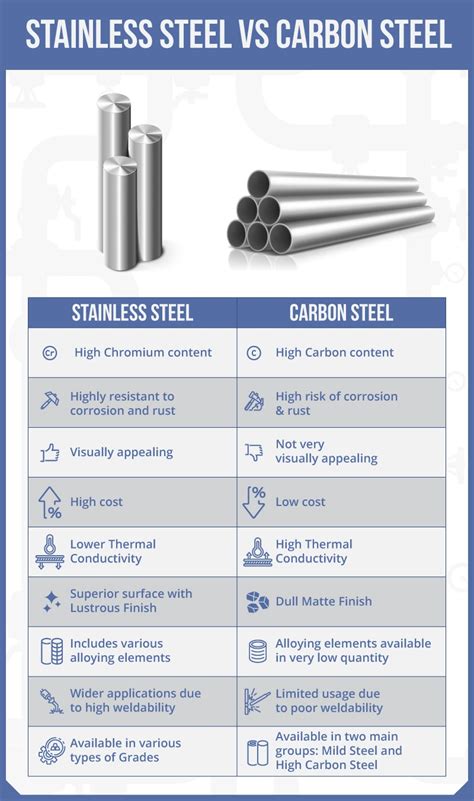

Comparison of Carbon and Stainless Steel

A direct comparison of carbon and stainless steel reveals significant differences in their properties. Carbon has a higher strength-to-weight ratio, making it ideal for applications where weight reduction is crucial. However, stainless steel excels in terms of corrosion resistance, particularly in environments with high humidity or exposure to chemicals.

| Property | Carbon | Stainless Steel |

|---|---|---|

| Strength-to-Weight Ratio | High | Medium |

| Corrosion Resistance | Medium | High |

| Thermal Conductivity | High | Low |

| Cost | Medium | High |

Applications of Carbon and Stainless Steel

Carbon’s unique properties have led to its widespread adoption in various industries. In aerospace, carbon fibers are used to manufacture lightweight yet strong components, such as aircraft wings and fuselage. In sports equipment, carbon is used to create high-performance products, such as golf clubs, bicycle frames, and tennis rackets.

Stainless steel, on the other hand, is commonly used in construction, automotive, and consumer products. Its corrosion resistance and durability make it an ideal material for building facades, automotive trim, and kitchen appliances. Stainless steel's aesthetic appeal has also led to its use in architectural features, such as handrails, door handles, and decorative trim.

Limitations of Carbon and Stainless Steel

While both materials have their advantages, they also have limitations. Carbon’s susceptibility to fatigue and its relatively high cost have limited its adoption in certain applications. Stainless steel, on the other hand, is prone to pitting corrosion and has a high cost due to the expensive production process.

In addition, stainless steel's high nickel content has raised concerns about its potential impact on human health and the environment. The extraction and processing of nickel have been linked to environmental degradation and health problems, making stainless steel a less sustainable option.

What is the main difference between carbon and stainless steel?

+The main difference between carbon and stainless steel lies in their properties and applications. Carbon is a versatile material with high strength-to-weight ratio, corrosion resistance, and thermal conductivity, making it suitable for aerospace, sports equipment, and other high-performance applications. Stainless steel, on the other hand, is renowned for its corrosion resistance, durability, and aesthetic appeal, making it a popular choice for construction, automotive, and consumer products.

Which material is more corrosion-resistant?

+Stainless steel is generally more corrosion-resistant than carbon, particularly in environments with high humidity or exposure to chemicals. However, carbon's corrosion resistance can be enhanced through surface treatments or coatings.

What are the limitations of carbon and stainless steel?

+Carbon's limitations include its susceptibility to fatigue and its relatively high cost. Stainless steel's limitations include its high cost, potential impact on human health and the environment, and susceptibility to pitting corrosion.

In conclusion, the choice between carbon and stainless steel depends on a variety of factors, including cost, weight, and environmental conditions. While both materials have their unique properties and applications, they also have limitations that must be considered. By understanding the differences between carbon and stainless steel, we can make informed decisions about which material to use for a specific application, ultimately leading to improved performance, safety, and sustainability.