The binding machine is a crucial piece of equipment in various industries, including printing, publishing, and office settings. Its primary function is to attach multiple pages together, creating a single, cohesive document. With the advent of digital technology, the demand for binding machines has evolved, and modern models now offer a range of features and functionalities to cater to diverse needs. In this article, we will delve into the world of binding machines, exploring their history, types, and applications, as well as the benefits and considerations of using these devices.

Key Points

- The binding machine has a long history, dating back to the 19th century, with early models using staples or sewing to bind pages together.

- There are several types of binding machines, including thermal, tape, spiral, and perfect binding, each with its own strengths and weaknesses.

- Binding machines are used in various industries, including printing, publishing, and office settings, for tasks such as report binding, thesis binding, and catalog creation.

- Modern binding machines offer a range of features, including automatic page turning, booklet making, and hole punching, to streamline the binding process.

- When selecting a binding machine, considerations include the type of binding, page capacity, and machine durability, as well as the cost and maintenance requirements.

History of Binding Machines

The concept of binding pages together dates back to ancient civilizations, with early methods including sewing, gluing, and stapling. The first mechanical binding machine was patented in the 19th century, and it used a combination of staples and glue to bind pages together. Over the years, binding machines have evolved to incorporate new technologies and features, such as thermal binding, tape binding, and spiral binding. Today, binding machines are an essential tool in many industries, offering a efficient and cost-effective way to create professional-looking documents.

Types of Binding Machines

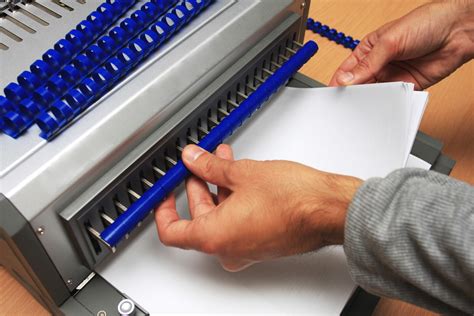

There are several types of binding machines available, each with its own strengths and weaknesses. Thermal binding machines use heat to bind pages together, creating a strong and durable bond. Tape binding machines use a strip of tape to attach pages together, offering a flexible and easy-to-use solution. Spiral binding machines use a spiral coil to bind pages together, creating a compact and easily accessible document. Perfect binding machines use a combination of glue and pressure to bind pages together, creating a professional-looking document with a flat spine.

| Type of Binding Machine | Description | Applications |

|---|---|---|

| Thermal Binding Machine | Uses heat to bind pages together | Report binding, thesis binding, and catalog creation |

| Tape Binding Machine | Uses a strip of tape to attach pages together | Office documents, presentations, and proposals |

| Spiral Binding Machine | Uses a spiral coil to bind pages together | Notebooks, journals, and calendars |

| Perfect Binding Machine | Uses a combination of glue and pressure to bind pages together | Books, magazines, and catalogs |

Applications of Binding Machines

Binding machines are used in various industries, including printing, publishing, and office settings. In the printing industry, binding machines are used to create professional-looking documents, such as reports, proposals, and catalogs. In the publishing industry, binding machines are used to create books, magazines, and journals. In office settings, binding machines are used to create presentations, reports, and documents, as well as to bind together loose pages and create a cohesive document.

Benefits of Using Binding Machines

Binding machines offer a range of benefits, including increased efficiency, cost savings, and professional-looking documents. With a binding machine, users can quickly and easily bind together multiple pages, creating a single, cohesive document. This can save time and money, as well as improve the overall appearance of the document. Additionally, binding machines can help to reduce waste and minimize the environmental impact of document production.

In conclusion, binding machines are a crucial piece of equipment in many industries, offering a efficient and cost-effective way to create professional-looking documents. With a range of features and functionalities, modern binding machines can cater to diverse needs and applications. By understanding the different types of binding machines and their applications, users can make an informed decision and choose the right machine for their needs.

What is the most common type of binding machine?

+The most common type of binding machine is the thermal binding machine, which uses heat to bind pages together.

What are the benefits of using a binding machine?

+The benefits of using a binding machine include increased efficiency, cost savings, and professional-looking documents.

How do I choose the right binding machine for my needs?

+To choose the right binding machine, consider the type of binding, page capacity, and machine durability, as well as the cost and maintenance requirements.