Ammonia refrigeration is a vital component in various industrial processes, particularly in the food processing, cold storage, and pharmaceutical sectors. The use of ammonia as a refrigerant dates back to the late 19th century, and its popularity endures due to its excellent thermodynamic properties, environmental friendliness, and cost-effectiveness. With a global warming potential (GWP) of zero and an ozone depletion potential (ODP) of zero, ammonia is an attractive alternative to traditional halogenated refrigerants, which are being phased down due to their significant impact on climate change and stratospheric ozone depletion.

The ammonia refrigeration system operates on the principle of absorption and vaporization of ammonia, which absorbs heat from the surrounding environment and transfers it to a condenser, where it is dissipated. This process is facilitated by the unique properties of ammonia, including its high latent heat of vaporization, which enables efficient heat transfer, and its relatively low boiling point, which allows for effective refrigeration at temperatures as low as -30°C. Furthermore, ammonia's non-toxic and non-flammable characteristics make it an ideal choice for applications where safety is paramount.

Key Points

- Ammonia refrigeration offers excellent thermodynamic properties, making it suitable for various industrial applications.

- The system's environmental friendliness, with a GWP and ODP of zero, positions it as a preferred alternative to traditional halogenated refrigerants.

- Ammonia's high latent heat of vaporization and relatively low boiling point enable efficient heat transfer and effective refrigeration at low temperatures.

- The non-toxic and non-flammable characteristics of ammonia ensure a safe operating environment.

- Regular maintenance and proper system design are crucial to optimizing the performance and safety of ammonia refrigeration systems.

System Components and Operation

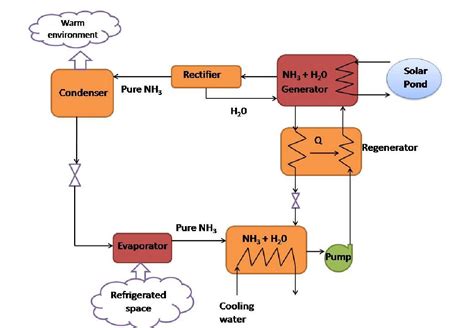

The ammonia refrigeration system consists of several key components, including the compressor, condenser, expansion valve, and evaporator. The compressor plays a critical role in compressing the ammonia vapor, which is then cooled in the condenser, causing it to condense into a liquid. The expansion valve reduces the pressure of the liquid ammonia, allowing it to expand and vaporize in the evaporator, where it absorbs heat from the surrounding environment. The vaporized ammonia is then drawn back into the compressor, and the cycle repeats.

Compressor Selection and Optimization

The selection and optimization of the compressor are critical to the efficient operation of the ammonia refrigeration system. Factors such as compressor type, capacity, and efficiency must be carefully considered to ensure that the system meets the required cooling demands while minimizing energy consumption. Screw compressors, reciprocating compressors, and centrifugal compressors are commonly used in ammonia refrigeration systems, each with its unique characteristics and advantages.

| Compressor Type | Capacity Range | Efficiency |

|---|---|---|

| Screw Compressor | 100-1000 kW | 70-85% |

| Reciprocating Compressor | 10-500 kW | 60-80% |

| Centrifugal Compressor | 500-5000 kW | 80-90% |

Safety Considerations and Regulations

While ammonia is a safe and environmentally friendly refrigerant, it can be hazardous if not handled properly. Ammonia is toxic and can cause severe health effects, including respiratory problems and skin irritation, if inhaled or exposed to the skin. Therefore, it is crucial to follow strict safety protocols and regulations when working with ammonia refrigeration systems. The International Institute of Ammonia Refrigeration (IIAR) and the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) provide guidelines and standards for the safe design, installation, and operation of ammonia refrigeration systems.

Leak Detection and Repair

Leak detection and repair are critical components of ammonia refrigeration system maintenance. Ammonia leaks can occur due to various factors, including corrosion, faulty connections, or worn-out components. Regular inspections and the use of leak detection equipment can help identify potential leaks, allowing for prompt repair and minimizing downtime. It is essential to follow established procedures for leak detection and repair, including the use of personal protective equipment (PPE) and ventilation systems to prevent exposure to ammonia.

What are the primary advantages of ammonia refrigeration systems?

+The primary advantages of ammonia refrigeration systems include their excellent thermodynamic properties, environmental friendliness, and cost-effectiveness. Ammonia's high latent heat of vaporization and relatively low boiling point enable efficient heat transfer and effective refrigeration at low temperatures.

What safety precautions should be taken when working with ammonia refrigeration systems?

+When working with ammonia refrigeration systems, it is essential to follow strict safety protocols and regulations, including the use of personal protective equipment (PPE), ventilation systems, and established procedures for leak detection and repair. Regular training and education on ammonia handling and safety are also crucial to preventing accidents and ensuring a safe working environment.

What are the common applications of ammonia refrigeration systems?

+Ammonia refrigeration systems are commonly used in various industrial applications, including food processing, cold storage, and pharmaceutical sectors. They are also used in ice rinks, cold storage warehouses, and other facilities that require low-temperature refrigeration.

In conclusion, ammonia refrigeration systems offer a reliable, efficient, and environmentally friendly solution for various industrial applications. By understanding the system components, operation, and safety considerations, users can optimize the performance and safety of these systems, ensuring a safe and efficient refrigeration process. Regular maintenance, proper system design, and adherence to safety protocols and regulations are crucial to preventing accidents and ensuring a safe working environment.

Related Terms:

- Ammonia refrigeration training

- Ammonia refrigeration cycle

- Ammonia refrigeration system pdf

- Ammonia refrigeration companies

- Ammonia Refrigeration salary

- Ammonia refrigeration system diagram