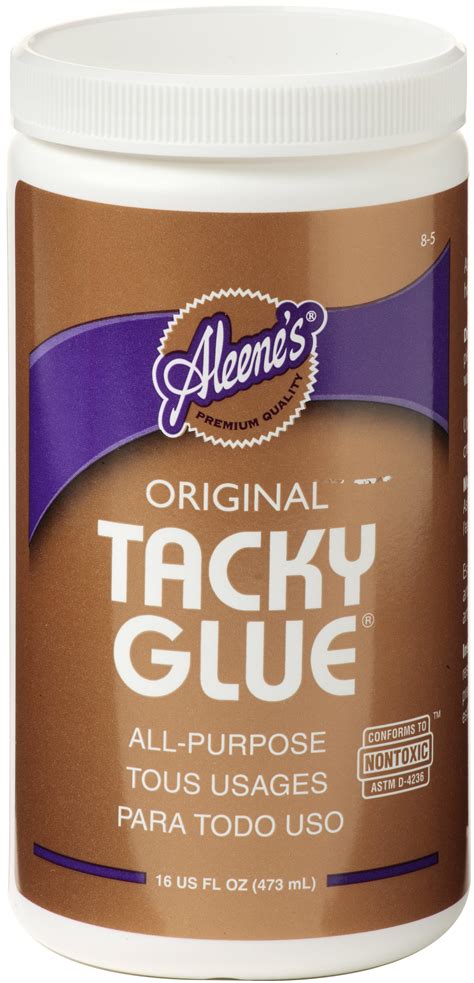

The concept of adhesive tacky refers to the stickiness or adhesive properties of a substance, particularly in the context of adhesives and coatings. Adhesive tacky is a critical parameter in various industrial applications, including packaging, construction, and manufacturing. In this article, we will delve into the world of adhesive tacky, exploring its definition, measurement, and significance in different fields.

Understanding Adhesive Tacky

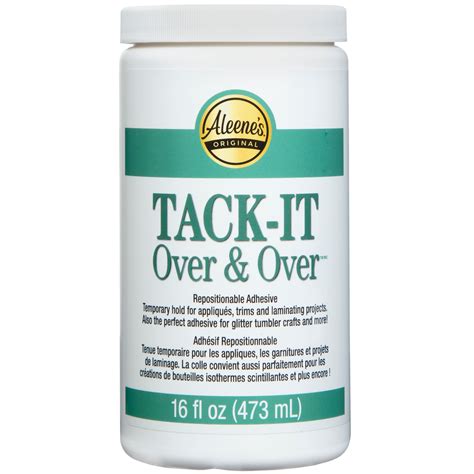

Adhesive tacky is a measure of the ability of an adhesive to form a bond with a substrate, typically characterized by its stickiness or tackiness. This property is essential in determining the suitability of an adhesive for a specific application. Adhesive tacky is influenced by various factors, including the chemical composition of the adhesive, its viscosity, and the surface properties of the substrate. A higher adhesive tacky value generally indicates a stronger bond between the adhesive and the substrate. However, excessive tackiness can lead to difficulties in handling and processing the adhesive.

Measurement of Adhesive Tacky

The measurement of adhesive tacky is typically performed using standardized tests, such as the Loop Tack Test or the Probe Tack Test. These tests involve applying a controlled amount of pressure to the adhesive and measuring the resulting force required to separate the adhesive from the substrate. The results are usually expressed in units of force per unit area, such as pounds per square inch (PSI) or pascals (Pa). The measurement of adhesive tacky is crucial in ensuring the quality and consistency of adhesives, as well as in optimizing their performance for specific applications.

| Adhesive Type | Adhesive Tacky (PSI) |

|---|---|

| Acrylic Adhesive | 10-20 |

| Rubber-Based Adhesive | 5-15 |

| Epoxy Adhesive | 20-30 |

Applications of Adhesive Tacky

Adhesive tacky plays a vital role in various industrial applications, including packaging, construction, and manufacturing. In packaging, adhesive tacky is essential in ensuring the secure closure of containers and the bonding of labels. In construction, adhesive tacky is critical in the bonding of materials, such as concrete, wood, and steel. In manufacturing, adhesive tacky is used in the assembly of products, such as electronics, automobiles, and aerospace components.

Factors Influencing Adhesive Tacky

Several factors can influence adhesive tacky, including temperature, humidity, and surface roughness. Temperature and humidity can affect the viscosity and chemical composition of the adhesive, leading to changes in its tackiness. Surface roughness can also impact adhesive tacky, as a rough surface can increase the contact area between the adhesive and the substrate, resulting in a stronger bond. Understanding these factors is essential in optimizing adhesive performance and ensuring the quality of adhesive-based products.

Key Points

- Adhesive tacky refers to the stickiness or adhesive properties of a substance.

- Adhesive tacky is influenced by factors such as chemical composition, viscosity, and surface properties.

- Measurement of adhesive tacky is typically performed using standardized tests, such as the Loop Tack Test or the Probe Tack Test.

- Adhesive tacky plays a vital role in various industrial applications, including packaging, construction, and manufacturing.

- Factors such as temperature, humidity, and surface roughness can influence adhesive tacky.

In conclusion, adhesive tacky is a critical parameter that can significantly impact the performance and reliability of adhesive-based systems. Understanding the factors that influence adhesive tacky and developing effective measurement techniques are crucial in optimizing adhesive performance and ensuring the quality of adhesive-based products. As research and development continue to advance, it is likely that new and innovative applications of adhesive tacky will emerge, further expanding the importance of this critical parameter in various industries.

What is adhesive tacky, and why is it important?

+Adhesive tacky refers to the stickiness or adhesive properties of a substance. It is essential in determining the suitability of an adhesive for a specific application and can significantly impact the performance and reliability of adhesive-based systems.

How is adhesive tacky measured?

+Adhesive tacky is typically measured using standardized tests, such as the Loop Tack Test or the Probe Tack Test. These tests involve applying a controlled amount of pressure to the adhesive and measuring the resulting force required to separate the adhesive from the substrate.

What factors can influence adhesive tacky?

+Several factors can influence adhesive tacky, including temperature, humidity, and surface roughness. Understanding these factors is essential in optimizing adhesive performance and ensuring the quality of adhesive-based products.

Meta description: “Discover the importance of adhesive tacky in various industrial applications, including packaging, construction, and manufacturing. Learn about the factors that influence adhesive tacky and how to measure it.” (150 characters)