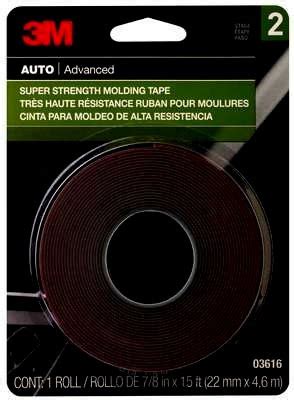

The automotive industry has witnessed significant advancements in recent years, with a growing focus on innovative materials and technologies that enhance vehicle performance, safety, and durability. One such material that has gained prominence is the 3M Double Sided Tape, a versatile and high-performance adhesive solution designed for a wide range of automotive applications. In this article, we will delve into the world of 3M Double Sided Tape, exploring its characteristics, benefits, and uses in the automotive sector.

Introduction to 3M Double Sided Tape

3M Double Sided Tape is a type of pressure-sensitive adhesive tape that features two adhesive sides, allowing it to bond two surfaces together. This unique design enables the tape to provide a strong and durable bond between various materials, including metals, plastics, and fabrics. The tape’s adhesive properties are engineered to withstand extreme temperatures, vibrations, and other environmental factors, making it an ideal solution for automotive applications.

Key Points

- 3M Double Sided Tape is a high-performance adhesive solution for automotive applications

- Features two adhesive sides for bonding two surfaces together

- Provides a strong and durable bond between various materials

- Withstands extreme temperatures, vibrations, and other environmental factors

- Used in a wide range of automotive applications, including interior trim, exterior trim, and electrical systems

Characteristics of 3M Double Sided Tape

3M Double Sided Tape is available in a range of thicknesses, widths, and adhesive strengths, allowing manufacturers to select the optimal product for their specific application. The tape’s adhesive properties are designed to provide a strong and durable bond, while its flexible design enables it to conform to complex shapes and surfaces. Additionally, the tape is resistant to extreme temperatures, ranging from -40°C to 150°C, making it suitable for use in a variety of automotive environments.

| Characteristic | Value |

|---|---|

| Adhesive Strength | Up to 400 N/10mm |

| Temperature Range | -40°C to 150°C |

| Thickness | 0.05mm to 1.5mm |

| Width | Up to 1000mm |

Applications of 3M Double Sided Tape in the Automotive Industry

3M Double Sided Tape is used in a wide range of automotive applications, including interior trim, exterior trim, and electrical systems. The tape is used to bond various materials, such as plastics, metals, and fabrics, and is particularly useful in applications where traditional fastening methods, such as screws or rivets, are not feasible. Some common applications of 3M Double Sided Tape in the automotive industry include:

- Interior trim: bonding dashboard components, trim panels, and other interior components

- Exterior trim: bonding exterior trim components, such as emblems, badges, and molding

- Electrical systems: bonding electrical components, such as wire harnesses and connectors

- Body and chassis: bonding body and chassis components, such as panels and frames

Benefits of Using 3M Double Sided Tape in Automotive Applications

The use of 3M Double Sided Tape in automotive applications offers a range of benefits, including:

- Weight reduction: the tape is significantly lighter than traditional fastening methods, contributing to overall vehicle weight reduction

- Improved durability: the tape provides a strong and durable bond, resistant to extreme temperatures, vibrations, and other environmental factors

- Increased design flexibility: the tape enables designers to create complex shapes and designs, without the need for traditional fastening methods

- Reduced production time: the tape is easy to apply, reducing production time and increasing manufacturing efficiency

Conclusion

In conclusion, 3M Double Sided Tape is a versatile and high-performance adhesive solution that has gained significant prominence in the automotive industry. Its unique design, characteristics, and benefits make it an ideal solution for a wide range of automotive applications, from interior trim to electrical systems. As the industry continues to evolve, we can expect to see even more innovative applications of this technology, driving further advancements in vehicle performance, safety, and durability.

What is 3M Double Sided Tape used for in the automotive industry?

+3M Double Sided Tape is used in a wide range of automotive applications, including interior trim, exterior trim, and electrical systems. It is used to bond various materials, such as plastics, metals, and fabrics, and is particularly useful in applications where traditional fastening methods are not feasible.

What are the benefits of using 3M Double Sided Tape in automotive applications?

+The use of 3M Double Sided Tape in automotive applications offers a range of benefits, including weight reduction, improved durability, increased design flexibility, and reduced production time. The tape is significantly lighter than traditional fastening methods, provides a strong and durable bond, and enables designers to create complex shapes and designs without the need for traditional fastening methods.

What are the characteristics of 3M Double Sided Tape?

+3M Double Sided Tape is available in a range of thicknesses, widths, and adhesive strengths, allowing manufacturers to select the optimal product for their specific application. The tape's adhesive properties are designed to provide a strong and durable bond, while its flexible design enables it to conform to complex shapes and surfaces. Additionally, the tape is resistant to extreme temperatures, ranging from -40°C to 150°C, making it suitable for use in a variety of automotive environments.

Meta description: “Discover the benefits and applications of 3M Double Sided Tape in the automotive industry, from interior trim to electrical systems. Learn how this versatile and high-performance adhesive solution can improve vehicle performance, safety, and durability.” (149 characters)