The advent of 3D printing technology has revolutionized the manufacturing landscape, enabling the creation of complex geometries and customized products with unprecedented ease. Among the various materials used in 3D printing, carbon fiber has garnered significant attention due to its exceptional strength-to-weight ratio, making it an ideal choice for applications where lightweight yet robust structures are required. In this article, we will delve into the realm of 3D printers that print carbon fiber, exploring their capabilities, benefits, and potential applications.

Introduction to Carbon Fiber 3D Printing

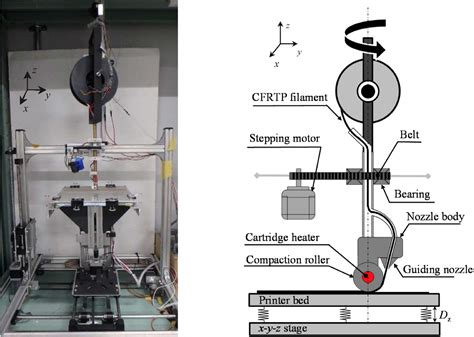

Carbon fiber, a material composed of long chains of carbon atoms, is renowned for its remarkable mechanical properties. When infused into a 3D printing material, such as a thermoplastic, it enhances the printed part’s stiffness, strength, and thermal stability. The process of 3D printing with carbon fiber involves extruding a carbon fiber-reinforced filament through a heated nozzle, which is then deposited layer by layer to form the desired shape. This technology has been gaining traction in various industries, including aerospace, automotive, and sports equipment manufacturing, where the unique properties of carbon fiber can be fully leveraged.

Key Points

- Carbon fiber 3D printing offers enhanced mechanical properties, such as increased strength and stiffness.

- The technology is particularly suited for applications where lightweight yet robust structures are required.

- Carbon fiber 3D printing is being adopted in industries like aerospace, automotive, and sports equipment manufacturing.

- The process involves extruding a carbon fiber-reinforced filament through a heated nozzle.

- Post-processing techniques, such as machining and surface treatment, can be applied to enhance the printed part's properties.

Benefits of Carbon Fiber 3D Printing

The integration of carbon fiber into 3D printing offers several benefits, including enhanced mechanical properties, reduced weight, and increased design flexibility. By leveraging these advantages, manufacturers can create complex geometries that cannot be produced with traditional manufacturing methods, thereby optimizing product performance and reducing material waste. Furthermore, the use of carbon fiber 3D printing can lead to significant cost savings, as it eliminates the need for tooling and molds, and enables the rapid production of customized parts.

| Property | Carbon Fiber 3D Printed Part | Traditional Carbon Fiber Part |

|---|---|---|

| Tensile Strength | 400-500 MPa | 600-700 MPa |

| Stiffness | 20-30 GPa | 30-40 GPa |

| Weight Reduction | 30-50% | 10-30% |

Applications of Carbon Fiber 3D Printing

The unique properties of carbon fiber 3D printed parts make them an attractive choice for a wide range of applications. In the aerospace industry, for instance, carbon fiber 3D printing is used to produce lightweight components, such as satellite parts and aircraft structures, which can lead to significant fuel savings and increased payload capacity. Similarly, in the automotive sector, carbon fiber 3D printing is being explored for the production of vehicle components, such as car bodies and chassis, which can enhance vehicle performance and reduce emissions. Additionally, carbon fiber 3D printing is being used in the sports equipment industry to create high-performance products, such as bicycle frames and golf clubs, which can provide athletes with a competitive edge.

Challenges and Limitations

While carbon fiber 3D printing offers numerous benefits, it is not without its challenges and limitations. One of the primary concerns is the high cost of carbon fiber materials, which can make it difficult for manufacturers to adopt this technology. Additionally, the process of 3D printing with carbon fiber requires specialized equipment and expertise, which can be a barrier to entry for some companies. Furthermore, the mechanical properties of carbon fiber 3D printed parts can be affected by various factors, such as the type of carbon fiber used, the printing parameters, and the post-processing techniques employed.

Future Developments and Trends

As the technology continues to evolve, we can expect to see significant advancements in the field of carbon fiber 3D printing. One of the key areas of development is the creation of new carbon fiber materials with enhanced mechanical properties, such as higher strength and stiffness. Additionally, researchers are exploring the use of advanced printing technologies, such as selective laser sintering (SLS) and stereolithography (SLA), to produce carbon fiber parts with improved surface finish and accuracy. Furthermore, the integration of carbon fiber 3D printing with other manufacturing technologies, such as CNC machining and injection molding, is expected to enable the production of complex hybrid structures with optimized properties.

What are the primary benefits of carbon fiber 3D printing?

+The primary benefits of carbon fiber 3D printing include enhanced mechanical properties, reduced weight, and increased design flexibility. Additionally, the technology enables the rapid production of customized parts, which can lead to significant cost savings and improved product performance.

What are the common applications of carbon fiber 3D printing?

+Carbon fiber 3D printing is being used in various industries, including aerospace, automotive, and sports equipment manufacturing. The technology is particularly suited for applications where lightweight yet robust structures are required, such as the production of satellite parts, aircraft structures, and high-performance sports equipment.

What are the challenges and limitations associated with carbon fiber 3D printing?

+The challenges and limitations associated with carbon fiber 3D printing include the high cost of carbon fiber materials, the need for specialized equipment and expertise, and the potential for mechanical property variations due to printing parameters and post-processing techniques. Additionally, the technology is still evolving, and further research is required to fully understand its capabilities and limitations.

In conclusion, carbon fiber 3D printing is a rapidly evolving technology that has the potential to revolutionize various industries by enabling the creation of complex, lightweight, and high-performance structures. While the technology is still facing challenges and limitations, the benefits it offers make it an attractive choice for manufacturers seeking to optimize product performance, reduce material waste, and improve production efficiency. As the technology continues to advance, we can expect to see significant developments in the field of carbon fiber 3D printing, including the creation of new materials, the improvement of printing technologies, and the integration with other manufacturing methods.