The world of sandpaper is a nuanced one, filled with varying grits and types, each designed for specific tasks and surfaces. Among these, 1000 grit sandpaper holds a unique position, bridging the gap between coarse and fine sanding. It's a tool that's often overlooked in favor of its more aggressive or finer counterparts, yet it serves a crucial purpose in the preparation and finishing of surfaces. To understand the role and benefits of 1000 grit sandpaper, it's essential to delve into the world of sanding, exploring the basics of grit sizes, the applications of 1000 grit sandpaper, and its advantages in various projects.

Understanding Grit Sizes

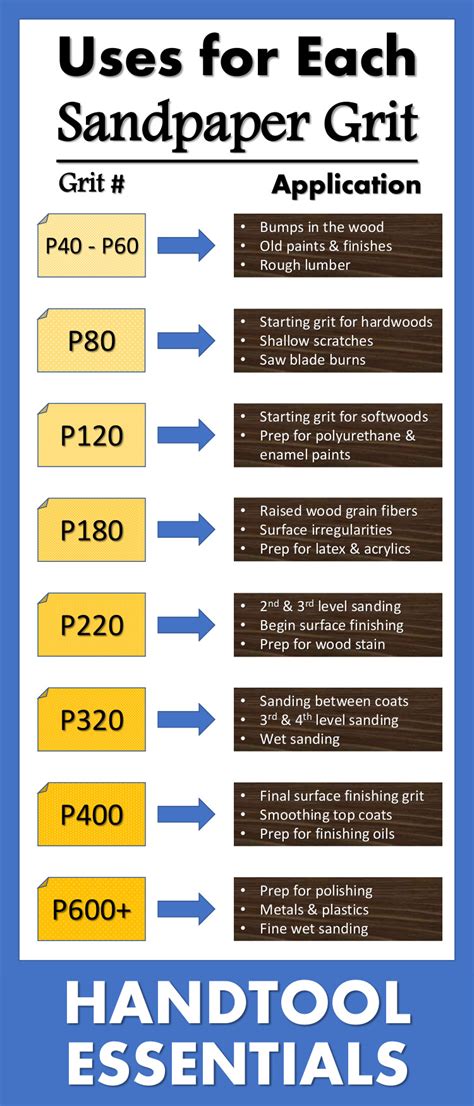

In the realm of sandpaper, grit refers to the size of the abrasive particles on the paper. The grit size is inversely related to the size of the particles - the higher the grit number, the smaller the particles. Generally, grit sizes range from very coarse (about 60-80 grit) to extremely fine (1200 grit and beyond). The choice of grit size depends on the task at hand, with coarser grits used for removing material and finer grits for polishing and smoothing surfaces. 1000 grit sandpaper falls into the fine grit category, making it suitable for the final stages of sanding before applying a finish or for polishing out minor scratches and imperfections.

Applications of 1000 Grit Sandpaper

The versatility of 1000 grit sandpaper makes it a valuable addition to any workshop or DIY project. It’s particularly useful for sanding wood, metal, and drywall, providing a smooth finish that’s ready for painting, staining, or applying a clear coat. In woodworking, 1000 grit sandpaper can be used to sand down finishes, preparing the surface for a new coat, or to remove minor imperfections in the wood. For metalworking, it helps in polishing metal surfaces, removing small scratches, and preparing the metal for paint or a clear protective coating. Additionally, in drywall finishing, 1000 grit sandpaper is used to smooth out joint compound, ensuring a flawless finish.

| Material | Application |

|---|---|

| Wood | Sanding down finishes, removing imperfections |

| Metal | Polishing, removing small scratches |

| Drywall | Smoothing out joint compound |

Benefits and Considerations

One of the primary benefits of using 1000 grit sandpaper is its ability to provide a high-quality finish with minimal effort. It’s effective at removing small imperfections and scratches, leaving the surface smooth and ready for the next step in the finishing process. However, it’s also important to consider the limitations of 1000 grit sandpaper. It may not be aggressive enough to remove deeper scratches or significant amounts of material, and for such tasks, a coarser grit sandpaper may be more appropriate. Furthermore, the choice between wet and dry sandpaper depends on the specific application and the material being sanded. Wet sanding with 1000 grit sandpaper can help prevent dust and reduce clogging of the sandpaper, but it may also require a specialized water-resistant sandpaper.

Technical Specifications and Considerations

When selecting 1000 grit sandpaper, several technical specifications and considerations come into play. The backing material (paper or cloth), the type of abrasive (aluminum oxide, silicon carbide, etc.), and the presence of any additives or treatments (such as waterproof coatings) can all impact the sandpaper’s performance. For most applications, aluminum oxide sandpaper is a good choice due to its durability and effectiveness on a wide range of materials. Additionally, the sandpaper’s size and shape can influence its usability, with smaller sheets being more manageable for detail work and larger sheets better suited for covering big areas.

Key Points

- 1000 grit sandpaper is ideal for fine sanding and polishing, providing a smooth finish.

- It's suitable for various materials, including wood, metal, and drywall.

- The choice of sandpaper type (wet/dry, aluminum oxide/silicon carbide) depends on the application and material.

- Technique and quality of the sandpaper are crucial for achieving a perfect finish.

- Always sand with the wood grain and use a sanding block for flat surfaces.

In conclusion, 1000 grit sandpaper is a versatile and essential tool for anyone involved in woodworking, metalworking, or drywall finishing. Its ability to provide a smooth, high-quality finish makes it an indispensable asset in the preparation and finishing stages of projects. By understanding the applications, benefits, and technical considerations of 1000 grit sandpaper, individuals can make informed decisions about when to use it and how to get the best results from their sanding efforts.

What is the primary use of 1000 grit sandpaper?

+The primary use of 1000 grit sandpaper is for fine sanding and polishing, providing a smooth finish on various materials such as wood, metal, and drywall.

How do I choose the right type of 1000 grit sandpaper for my project?

+The choice of 1000 grit sandpaper type (wet/dry, aluminum oxide/silicon carbide) depends on the application and the material being sanded. Consider the surface you’re working on and the desired finish to select the appropriate sandpaper.

What technique should I use when sanding with 1000 grit sandpaper?

+Always sand with the wood grain to avoid scratches, and use a sanding block for flat surfaces to prevent uneven sanding. This technique helps in achieving a smooth, high-quality finish.